Glass marbles are timeless toys and decorative items that have fascinated people for generations. Their smooth texture, vibrant colors, and perfect round shapes are achieved through a meticulous production process. Understanding how glass marbles are made can enhance our appreciation for these small but intricate objects. This article delves into the detailed steps involved in the production of glass marbles, ensuring an optimized approach for better online visibility.

Raw Material Preparation

The production of glass marbles begins with the selection of high-quality raw materials. The primary component is silica sand, known for its purity and clarity. This is combined with soda ash and limestone to create a glass mixture. These ingredients are carefully measured and mixed to achieve the desired properties of the final product.

Melting

Once the raw materials are prepared, they are transferred into a furnace. The furnace heats the mixture to approximately 1700°C, causing it to melt and form a molten glass. This high-temperature environment is crucial for achieving a homogenous molten state, which is essential for the next stages of marble formation.

Forming

The molten glass is then directed into a marble-making machine. Here, it is cut into small, uniform pieces. These pieces are rolled into spherical shapes through a combination of gravity and machine-guided rolling mechanisms. This process ensures that each piece of glass takes on the iconic marble shape we are familiar with.

Annealing

After forming, the glass marbles undergo a process called annealing. They are slowly cooled in an annealing oven, which helps to remove internal stresses and prevent cracks or fractures. This controlled cooling process is vital for ensuring the marbles are durable and long-lasting.

Polishing

Once annealed, the marbles are polished to achieve their characteristic smooth and glossy surface. This step involves tumbling the marbles with abrasives that gradually refine their surface, making them suitable for both play and decorative purposes.

Quality Control

Quality control is an integral part of the production process. Each marble is inspected for uniformity in size, shape, and clarity. Marbles that do not meet the stringent quality standards are discarded or recycled. This step ensures that only the best products reach the market.

Packaging

Finally, the finished glass marbles are sorted and packaged according to customer specifications. They are often grouped by size and color, then counted and placed in bags or boxes for distribution. Proper packaging not only protects the marbles during transport but also makes them attractive to consumers.

Conclusion

The production of glass marbles is a complex process that combines traditional craftsmanship with modern technology. From the careful selection of raw materials to the precise forming and polishing stages, each step is essential in creating these beloved items. Understanding the production process highlights the skill and precision required to produce high-quality glass marbles. This article aims to provide an in-depth look at the intricate journey from raw material to finished product, enhancing our appreciation for these timeless treasures.

About Bloom Stone

Bloom Stone Manufacturer produce a variety of products: Glass Marbles,Glass Beads,Natural Stone, Polished Pebbles, Gravel Stones, Dyeing Gravels, Pebble Mosaic, Engraved Stone, Natural Agates and so on.

Please contact us for more products sales@njbloomstone.com

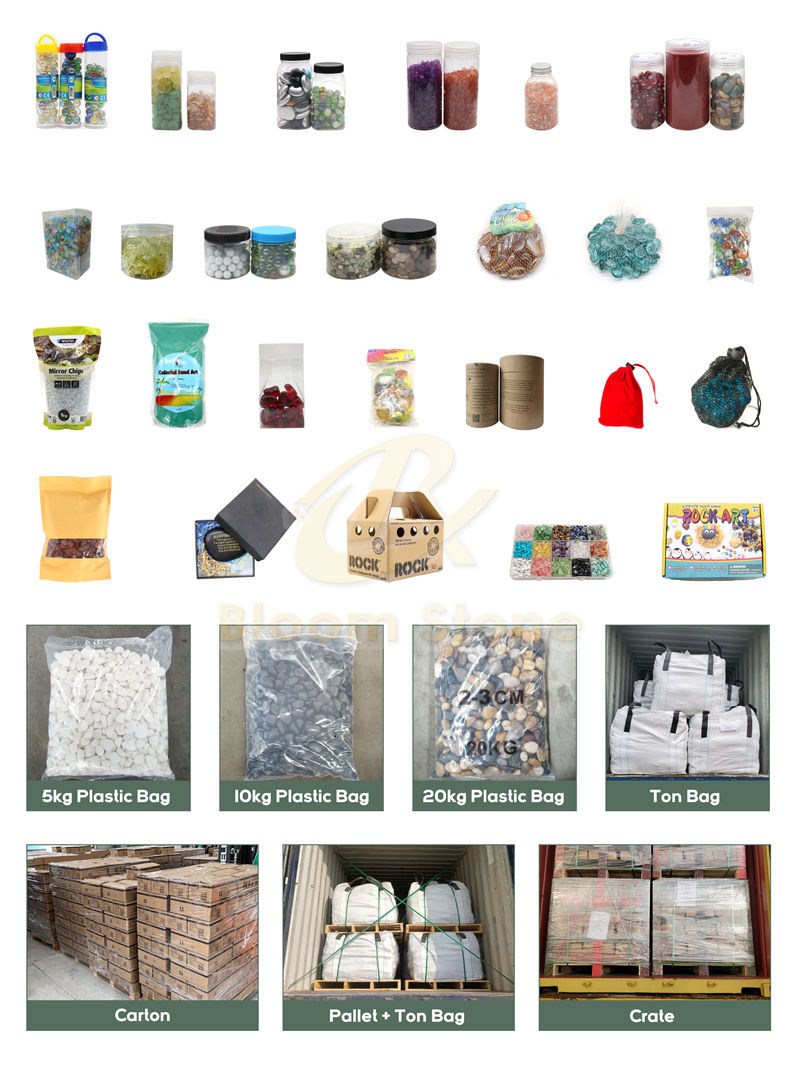

Packaging:

Our commitment to quality extends to our packaging solutions. Tumbled Snow White Pebble is available in a variety of packaging options tailored to your needs:

- Standard Packaging: Choose from 5kg, 10kg, 15kg, 20kg, and 25kg plastic bags or ton bags for bulk shipments, with the option to include pallets or wooden crates for added protection.

- Customized Packaging: Take advantage of our free design services to create custom-printed plastic bags and cardboard boxes that reflect your brand identity and enhance the presentation of our products.